Phoenixweld HW751 welding flux F7A2-EM12K

Aluminate Rutile Flux

Product Name:

Phoenixweld HW751 welding flux F7A2-EM12K

Specifications and Compliance:

GB/T 5293-2018 S43A0AR-SU08 S49A3AR-SU26

AWS A5.17M F6A0-EL8 F7A2-EM12K

General Information:

Basicity Index:1.1

Grain Size:12-60 mesh

Density:1.4g/cm3

Polarity:DCEP/AC

Application:

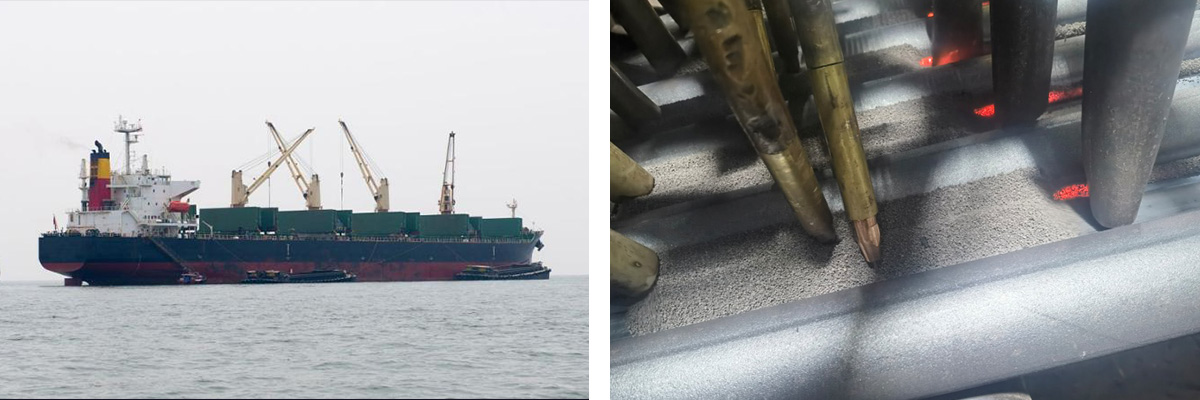

PHOENIXWELD HW751 fllux is acid flux. It can transit Si and Mn to the weld bead. It is insensitive to a small amount of rust and oxide scale and it has strong anti-porosity capability, which makes it especially suitable for the occasion when the base metal is not strictly cleaned before welding. It has good weld bead appearance, excellent slag removal and it is especially suitable for the high-speed fillet welding with double wire and multi-wire. It has excellent welding performance, stable arc combustion. The maximum welding current can be 1000A. It can weld low carbon steel, low alloy steel and heat resistant steel with proper welding wire. It is used for the welding of ships, boilers and pressure vessels.

Mechanical Properties:

|

Flux/Wire Combination |

Rm (Mpa) |

ReL / Rp0.2 |

A (%) |

V-groove Impact |

|

| -20℃(J) |

-29℃(J) |

||||

| SU26 |

465 |

375 |

32 |

120 |

/ |

| EM12K |

545 |

435 |

30 |

/ |

105 |

Notes:

1.Re-dry the flux at 300-350℃ for 60 minutes before welding.

2.Remove rust, water scale, primer and other contaminants on the base metal before welding to obtain excellent weld deposit.

3.Add new flux regularly before using the recycled flux to prevent defective weld bead.

Package:

25kg/moisture repellent bag,25kg/bucket,400kg/bulk bag

For special package, please contact us.

LEAVE MESSAGES

Thank you for your message, we will feedback after receiving the message the first time!

CONTACT US

Ms. Claire Wu

Phone: +86 371 6731 7666

Mobile:+86 156 1757 3337

Mailbox:phx@fenghuanghj.com

Address:NO.98 Dengfeng South Road,Shangjie District,Zhengzhou City

Copyright © Zhengzhou Phoenix New Material Technology Co., Ltd. 豫ICP备14018313号 Power by 300.cn

Submitted Successfully

Thank you for contacting Phoenix! We will be in touch soon.

+8615617573337

+8615617573337 WhatsApp

WhatsApp  phx@fenghuanghj.com

phx@fenghuanghj.com